Největší událost na Slovensku a v Česku zaměřená na neustálé zlepšování

Posláním Lean Summit CzechoSlovakia je vytvořit prostředí, kde mohou vedoucí pracovníci, odborníci, lídři a poskytovatelé řešení z různých odvětví diskutovat a vyměňovat si své zkušenosti v oblasti Lean, řízení změn, Change Management, Technology a Data-Driven Excellence.

Kdo se zúčastnil minulý rok?

4 tematické streamy

Inspirativní speakeři

Workshopy & Case Studies

Gemba Walks

Večerní Awards a večírek

Lean Summit CzechoSlovakia

V dnešním rychle se měnícím prostředí je klíčem k úspěchu schopnost pružně reagovat na nové výzvy. Budujte kulturu připravenosti na změny, pravidelně přehodnocujte svou organizační strukturu, schopnosti i procesy a hledejte technologie, které nejlépe podpoří vaše obchodní cíle. Podpořte inovace, zapojení lidí a využijte potenciál nového hybridního prostředí!

Událost

Hotel Passage Brno

Vítejte v znovuzrozené brněnské legendě. Postaven v roce 1928 jako metropolitní palác renomovaným architektem Bohuslavem Fuchsem.

V samém srdci Brna nyní nabízí prvotřídní restauraci a moderní kongresové centrum. Unikátní umělecké instalace vás přivítají od fasády až po interiér a dodávají mu na kouzlu a historii.

Spojte se a inspirujte se

Připojte se k více než 300 nadšeným, inovativním a otevřeným profesionálům z oblasti výroby a služeb. Získejte nové poznatky, inspiraci a objevte příležitosti, jak posunout své podnikání na vyšší úroveň.

Součástí programu je slavnostní banket a neformální předvečerní párty, které vám umožní navázat nejen nová profesionální partnerství, ale i cenná lidská přátelství. V příjemné atmosféře se snoubí odborné diskuse s osobními setkáními, která otevírají dveře k dlouhodobé spolupráci.

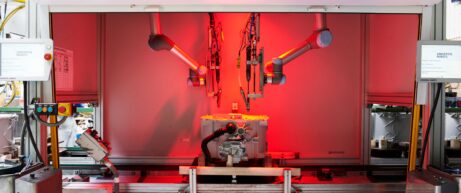

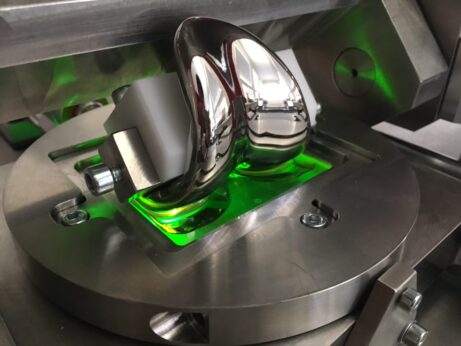

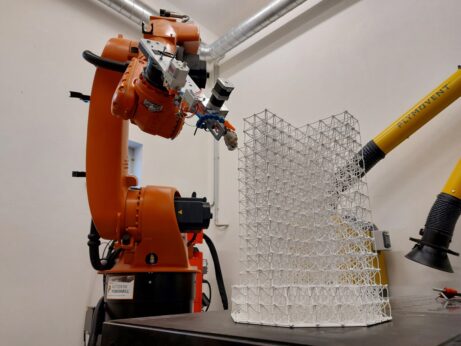

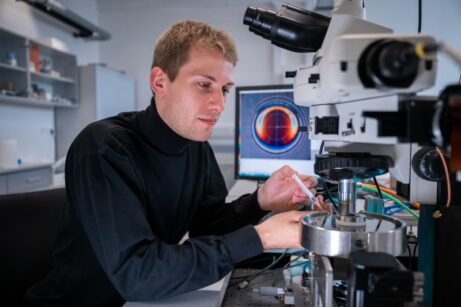

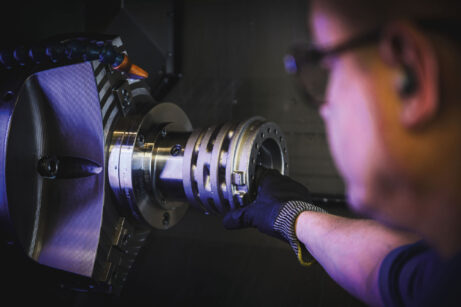

Gemba Walk

Live Plant Tour

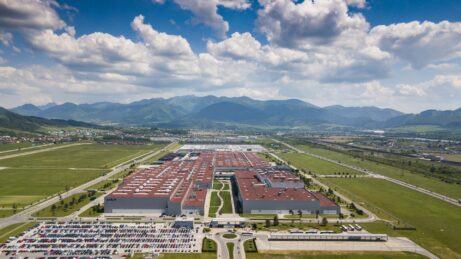

Letos budete mít příležitost zúčastnit se podrobné prohlídky závodu – Gemba Walk, která vám poskytne přímý pohled na zajímavé výrobní závody a nevýrobní společnosti v regionu Jižní Moravy. Nově bude součástí netradiční Gemba Walk v akademické sféře.

Koho můžete navštívit?

CommScope je světovým lídrem v oblasti komunikačních infrastrukturních řešení, která propojují lidi a technologie po celém světě.

ALPS Electric Czech, s.r.o. je českou pobočkou japonského nadnárodního koncernu tvořeného 79 firmami a více jak 42.000 zaměstnanci po celém světě.

Psychologický ústav Akademie věd České republiky

je popředním centrem psychologického výzkumu

v České republice.

Vysoké učení technické v Brně (VUT) je nejstarší brněnská univerzita zaměřená na technické, přírodovědné, ekonomické i umělecké obory.

Atlas Copco Services v Brně představuje moderní centrum sdílených služeb švédské společnosti Atlas Copco Group.

Walter s.r.o. je dceřinou společností firmy Walter Maschinenbau GmbH. Od roku 1996 sídlí v Kuřimi

u Brna v moderním výrobním a logistickém areálu, kde zaměstnává více než 250 osob.

Poclain je nezávislá průmyslová skupina se sídlem

ve Francii, která se specializuje na konstrukci, výrobu

a prodej hydrostatických a elektrohydraulických systémů.

Siemens Energy, s.r.o., o.z. Industrial Turbomachinery je přední výrobce průmyslových parních turbín s více než 120 letou tradicí.

Lufthansa InTouch Brno už více než 20 let stojí tam, kde se potkává technologie, lidskost a momenty, na kterých opravdu záleží.

Brzy přibudou další společnosti

4 paralelní streamy

Vaše Lean cesta začíná právě zde!

Nenechte si ujít příležitost zúčastnit se největší akce věnované Lean managementu v Česku a na Slovensku. Počet vstupenek je omezený.

Lístek pro 1 osobu

12 975 CZK

519 EUR

cena je za osobu bez DPH

Lístek pro 3+ osob

11 500 CZK

460 EUR

cena je za osobu bez DPH

Co je zahrnuto v ceně?

22. dubna 2026 vás čeká neformální večerní uvítací párty, která otevře summit v přátelské atmosféře.

23. dubna 2026 se ponoříte do celodenního programu plného inspirace: případové studie, interaktivní workshopy, přednášky hlavních řečníků a slavnostní předávání cen Lean Awards. Den zakončíme společným banketem, ideální příležitostí pro networking a sdílení zkušeností.

24. dubna 2026 uzavřeme summit návštěvami předních továren, kde získáte praktické poznatky a inspiraci přímo z prostředí špičkových firem.

Případové studie

Workshopy

Keynote řečníci

Video

Uvítací večírek

Občerstvení

Mobilní aplikace

Summit Banket

ORGANIZÁTOŘI SUMMITU

ORGANIZAČNÍ PARTNEŘI

Lean Summit sponzoři 2026

Gold

Silver

Bronze

Main Media Partner

Media Partner

Staňte se sponzorem Lean Summit CzechoSlovakia 2026

Máte zájem sponzorovat tuto akci? Nabízíme širokou škálu MOŽNOSTÍ PRO SPONZORY, jako například:

- Prostor pro sdílení vašich zkušeností a prokázání vaší odbornosti

- Výstavní prostor pro rozvíjení vztahů s vaším cílovým trhem

- Marketingová propagace pro zlepšení vaší reputace v oboru

Dana Janošíková

Lída Kiselová

Veronika Gregorková